Read any paper or article on supply chain management and one key factor returns time after time :

How engaged you are with your supply chain?

Let’s look at Best Practise

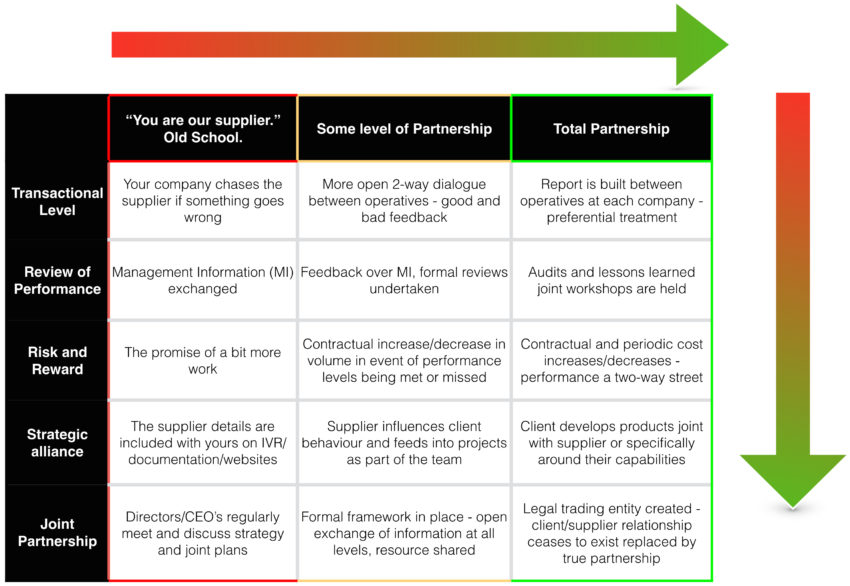

This is our summary of best practise in the industry: The idea is a very simple one; in order to get the best out of your supplier to move as close to the bottom right on this matrix; green and green!

We have not read an academic study that disagrees with the concept and research bodies such as Gallup Supplier Engagement concludes that there are real benefits to be had where engagement is proactively driven, including;

- Higher quality

- Improved forecasting and planning

- Improved product development

- Greater supplier support

- Lower costs – both transactional and price per piece overall

We are all agreed then – we follow best practise!

Seeing as we have this unanimously agreed, clearly every supply chain function follows these engagement guidelines!

Well, not quite.

Here are 3 factors that stand in our way:

1.Resource

It takes considerable effort and time to proactively drive engagement and dependant on the size of the supply chain function it will certainly never be practical to adopt this for all suppliers. The hard bit is to identify which one(s) are “worth” the effort – either through volume of orders, strategic importance, or quite frankly how well you get on with the supplier. So engagement happens in pockets with isolated suppliers.

2.Too few gains

As with all theoretical models, real life will always throw in a few curve-balls that break the consensus. In the past we have worked with suppliers who deliver a great product at a great price which completely fitted our business. Processes were automated, human intervention rare and issues numbers were through the floor. Simply put, it just didn’t seem we could do much more to drive performance and certainly the effort we would put in was never going to materialise in corresponding benefits.

3.Convinced they are already doing it

Someone from a supply chain function might look at the top left tangent and immediately think along the lines of “we may not be world class but at least we are better than that”. We’ve worked with supply chain managers and consultants from different sectors who on the question of engagement are all convinced that whilst there is always room for improvement, they ARE engaged with their supply chain.

But we do measure engagement!

The biggest challenge we would have to this is to understand how this engagement is measured; nine times out of ten it is by the criteria of the buyer, NOT the supplier. In other words it’s a one dimensional assessment which does nothing to further any engagement or relationship.

…and we do communicate!

Supply teams have argued that there is frequent exchanging of information, Management Information and service levels met, but these feel more of a contractual requirement and any meeting to discuss these WILL progress the relationship but by increments not leaps and bounds.

An easy first step to enlightenment

Tell your suppliers you want to engage better with them.

You might be trying, but they won’t notice unless you talk to them.

Discuss, together, how you might do this to best effect for both parties.

In an ideal world – bake it in from the start:

We’ve seen first hand companies and their strategic supplier launch joint ventures in a new territory with a board member from either side join the others board. This ensures that strategy, ambition and delivery was jointly conceived and the benefits (and profits) gained were shared equally.

Aspirational? Certainly. Always achievable? Certainly not.

But getting as close to this ideal as suits your company in terms of outlook, structure and resource is well worth the effort.

Don’t necessarily ask yourself what the cost benefits will be for this effort, rather what the price of not engaging might be.