Do you use the phrase “Supply Chain Partners”? Do you actually embody all the best practices of a partnership?

Partnership is a word used often, especially in supply chain management – “Supply chain partners”. But what does this actually mean in reality?

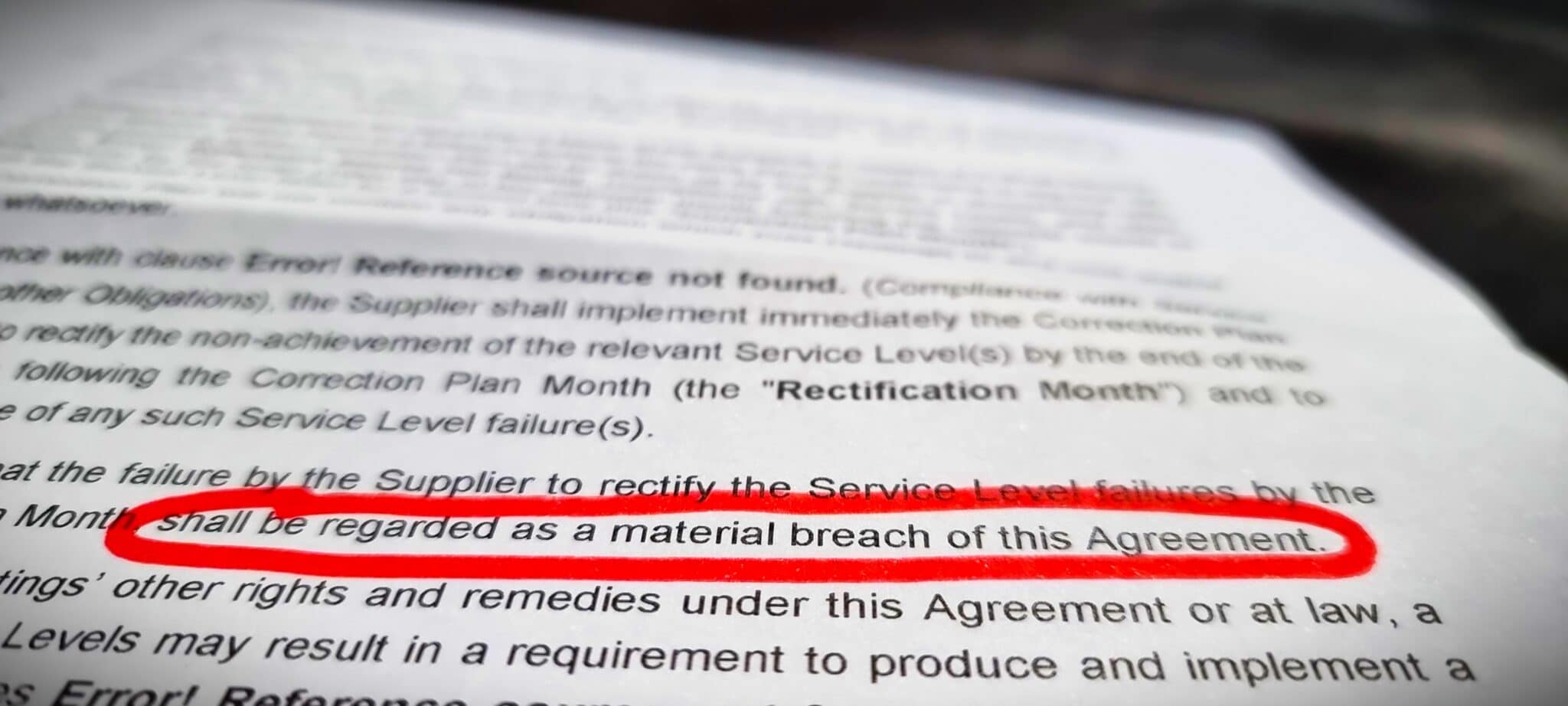

From experience, the short answer is nothing. After all, a name is just that. A name. Too often you will see the contract being referred to, clauses being quoted, service levels cited and even mention of service credits or breach. YOU the supplier, agreed to these terms so WE expect you to adhere to them.

So what? That’s supply chain management right there isn’t it – making sure the supply chain meet their obligations.

Have you ever wondered how your supply chain ranks YOUR ability to meet obligations?

Have you always paid on time or is there aged debt? Are the volumes you promised being delivered in order numbers?

Perhaps even more revealing, how do you think your suppliers rate YOU?

Many of our consultants have made the switch from buyer to supplier and all have said the same. Clients are great at talking about partnership but actually very bad at actually doing it. Because to create true partnerships it can never be a name or title, it has to be a whole new way of working.

“I know it is a tight deadline but the board need this information by 1pm tomorrow – please get it to me by 10am so I can review it.”

– Supply Chain Managers all over the world

It is such a common activity – the ad hoc information request. The reasons behind it are sound, the “emergency nature” justified. But does the contract allow it? Probably not. Would you, the client accept a request at no notice coming the other way? Almost certainly not.

But why does it matter?

Studies undertaken with supply chains from various sectors have all reported that a strong partnership approach brings a number of benefits to the client. These include;

- Costs. Suppliers confirmed that they were less likely to seek price increases in a partnership arrangement than a traditional supplier and client one. The operational costs to serve a demanding client are always higher than a reasonable client.

- Innovation. In an “open relationship” the supplier is more willing to bring new ideas forward for consideration. This is because they feel they have more of a valid voice in the venture.

- Sharing of market information and trends.

- Process improvements. Because you are working together, your suppliers are more likely to suggest and implement improvements for who you interact.

- Honesty and transparency. Last, but by far from least. If you are using the contract as a stick to beat your supplier, do not be surprised when your supply chain hide issues from you. Afterall, they see no benefit in bringing issues to the open.

So what practical steps can be taken to move towards a partnership approach?

- Ask “what can we do?”, not “what are you doing?”

Pushing any issue down the line only creates barriers. Approach the issue with the offer of help for mutual benefit.

- Do not keep quoting contract clauses every time you ask for something.

There is a time and place to refer to the contract. If you quote it on every interaction, it creates a sense of distrust. There is also the real risk that the supplier might start quoting it back to you. Contracts are a legal framework for your businesses to engage with each other, not an operational manual.

- Be open and transparent.

If your company has made errors that effects the supplier, do not hide them. Tell your supplier what the issue is, and what you are doing to resolve it. This encourages openness and for your supplier to do the same.

- Invest in your suppliers.

This does not have to be a financial investment but could be time or expertise.

If you identify leakage in any audit, consider not taking that money but asking the supplier to use this to fund improvements. - Ask your supplier to rank you

They will work with multiple clients – ask them how you compare. There might be a competitor who engages in a more productive way.

There are only so many hours in the day and so many members of your supply chain management team. Adopting a partnership approach to all suppliers is simply not practical. Nor will it always deliver results.

Segment your supply chain and identify your KEY suppliers. It is these that the focus should be on.

1. Segment your supply chain and identify your key suppliers.

2. Identify how you can help these suppliers.

3. Be open and transparent.

4. When you find problems with a supplier, ask them how you can help them fix it.

5. Ask your supplier how you can be better (for them) than your competitors.

Are you short on time?

Use these templates to help with this Best Practice:

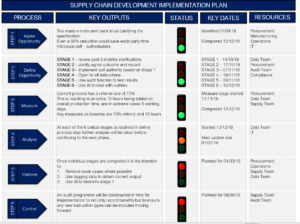

Supplier Segmentation (Excel)

To manage your supply chain, you need to segment suppliers accordingly so that your resources and efforts are spent in the right place. This template enables you to do this and has a detailed list of supplier activities required to effectively manage your supply chain.

See: Supplier Segmentation (Excel)Supply Chain and Procurement Management (Powerpoint)

A guide to supply chain and procurement activity to enable cost control of a supply chain. Provides an overview and detail of what to do.

See: Supply Chain and Procurement Management (Powerpoint)Supply Chain Costs Template (PowerPoint)

A step by step guide showing you how to establish and present your supply chain costs and how to start making savings.

See: Supply Chain Costs Template (PowerPoint)Supplier Status Report (Excel)

A dynamic supplier control template which has status indicators automatically updated by performance data.

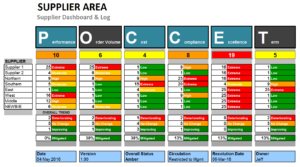

See: Supplier Status Report (Excel)Supplier Risk and Performance Dashboard Template (POCCET)

This Supplier Risk and Performance Dashboard template allows you to identify, present and manage the risk and performance of your Supplier portfolio.

See: Supplier Risk and Performance Dashboard Template (POCCET)Business Topics that support this Best Practice

Supply Chain Management

Supply Chain and Procurement Management (Powerpoint)

A guide to supply chain and procurement activity to enable cost control of a supply chain. Provides an overview and detail of what to do.

See: Supply Chain and Procurement Management (Powerpoint)Supply Chain Costs Template (PowerPoint)

A step by step guide showing you how to establish and present your supply chain costs and how to start making savings.

See: Supply Chain Costs Template (PowerPoint)Supplier Segmentation (Excel)

To manage your supply chain, you need to segment suppliers accordingly so that your resources and efforts are spent in the right place. This template enables you to do this and has a detailed list of supplier activities required to effectively manage your supply chain.

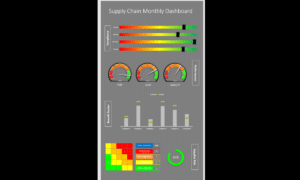

See: Supplier Segmentation (Excel)Supplier Monthly Dashboard (Mobile-Friendly Powerpoint)

This Mobile Friendly Dashboard is specifically designed to be viewed on a mobile, and for social media sharing. Communicate present supplier performance to your teams, stakeholders and executives while they work on the move.

See: Supplier Monthly Dashboard (Mobile-Friendly Powerpoint)