We flew Ryan Air recently and it was “interesting”, but what really stood out was at every stage the supply chain was held up to blame as the villain who was responsible for every small problem.

Our experience was actually not too bad; two flights, two delays, a grand total of about 3 hours delays over both legs which could be best described as irritating. There were no hoards of passengers beating down the pilots door or flooding the customer desk with compensation requests yet a scape goat was presented to accompany every update once delays set in.

- The flight is delayed because the incoming flight is late

- The take-off is delayed because airport provided ground staff are not available

- The take-off is further delayed because a third party hasn’t got the paperwork to air control on time

- The take-off is further delayed because air-control are being slow

- We’ve landed but this airports ground crew didn’t sort out a landing gate

- We’ve got a gate but Swiss Air staff haven’t arrived to open the doors yet

Talking amongst the passengers (we had a fair bit of time on our hands) the reaction to this was universal;

We don’t know how an airline works, we don’t care how an airline works, we paid ONE company so we expect that company to look after us.

The Supply Chain Shield

Blaming your own companies failings is way more common that people right realise; “it’s the other planes fault”, “our sales department let you down” etc. But over the years we have seen that whilst the blame might be readily allocated, the responsibility on behalf of the wider company is more often than not taken on board so in the eyes of the customer someone is owning the problem.

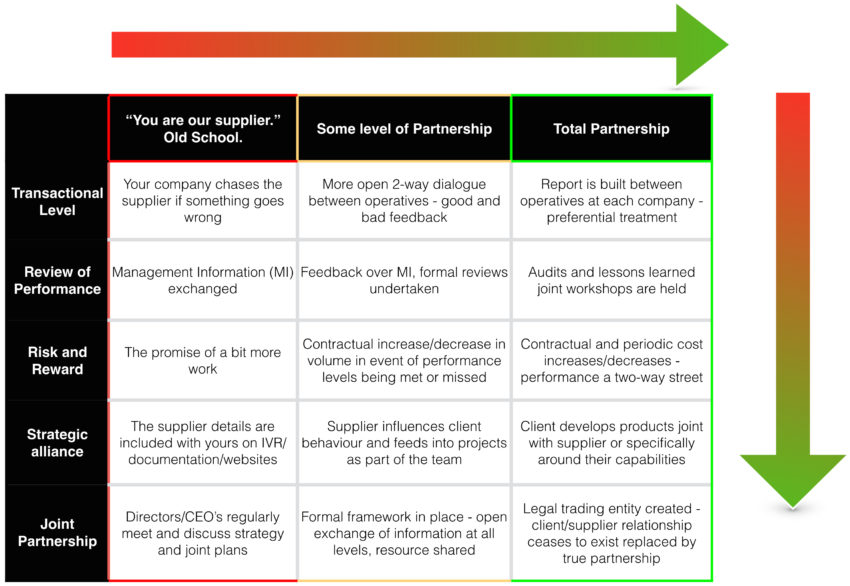

Not so when it comes to supply chain; there are still many interactions where the supply chain is held up like a defensive shield against all manner of complaints, the implication being that “We are good; THEY are not and are letting YOU down. NOT US”

Customers Perception

Has any customer ever, on hearing that it was a supplier not the main company they bought the service from, felt any different about the service they have received? We would say that at best no, and at worst it makes the situation even worse.

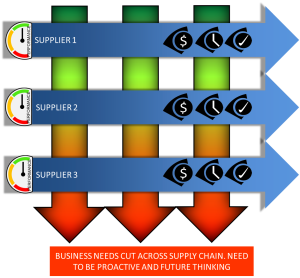

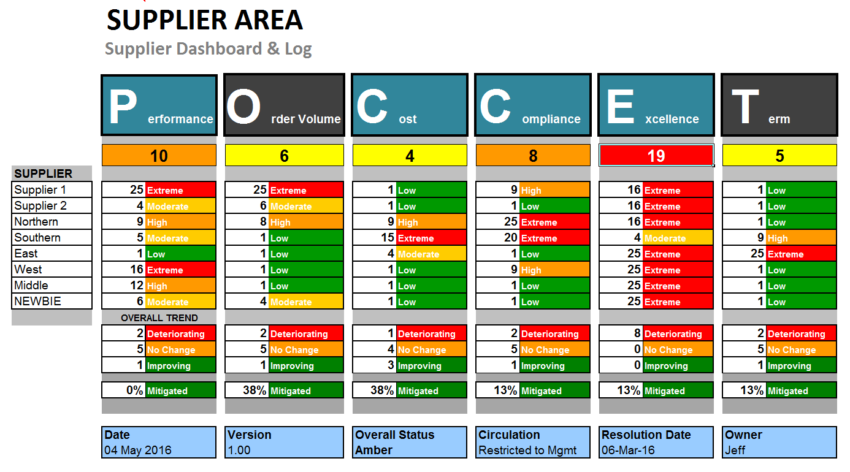

Ryan Air have chosen to outsource a large part of their operational service to reduce costs and increase efficiencies. Good for them. But don’t start blaming these companies when they don’t deliver. MANAGE the supply chain internally, don’t insult the customer by thinking we will forgive bad service or focus our frustrations on another company. We won’t; we paid YOU, not your suppliers, it’s your job to make them perform.

After all, should the experience on landing be world class thanks to the supplier, we wonder how many subsequent announcements are made saying “actually, its not us, that’s our supplier”?